|

Q.

How important are clean and checks?

A.

All heating and cooling systems should be serviced

every year by a heating and cooling professional.

For

furnaces, your service technician should:

•Check

for leaks, soot, rust, corroded electrical contacts

and frayed wires.

•Perform any necessary cleaning, including the

burner and heat exchanger.

•Inspect the venting system and verify that it

is operating properly.

For heat pumps and air conditioners, your technician

should:

•Inspect

all electrical connections.

•Check the operation of the compressor and outdoor

fan motor.

•Inspect the indoor evaporator coil for cleanliness

and clean if necessary.

•Inspect the furnace or air handler blower assembly

for proper operation and cleanliness.

•Check the refrigerant level in the system.

If the air conditioning or heat pump refrigerant level

is low, a proper leak check should be performed, and

the leak should be repaired or the leaking component

should be replaced.

Back

To Top

Q.

What should an HVAC technician check on my system?

A. All heating and cooling systems

should be serviced every year by a heating and cooling

professional.

For

furnaces, your service technician should:

•Check

for leaks, soot, rust, corroded electrical contacts

and frayed wires.

•Perform any necessary cleaning, including the

burner and heat exchanger.

•Inspect the venting system and verify that it

is operating properly.

For heat pumps and air conditioners, your technician

should:

•Inspect

all electrical connections.

•Check the operation of the compressor and outdoor

fan motor.

•Inspect the indoor evaporator coil for cleanliness

and clean if necessary.

•Inspect the furnace or air handler blower assembly

for proper operation and cleanliness.

•Check the refrigerant level in the system.

If the air conditioning or heat pump refrigerant level

is low, a proper leak check should be performed, and

the leak should be repaired or the leaking component

should be replaced.

Back

To Top

Q. How

often should I change my furnace filter?

A.

Replace

your furnace filter at the start of every heating and

cooling season.

In

environments with high dust or pets, ask your technician

about the option of a high-efficiency air filter or

electronic air cleaner that may need to be replaced

just once a year. They work at least seven times better

than a standard filter at removing dust and other particles.

Back

To Top

Q.

What

to do if the air conditioning won't come on:

A.

1.If

you have no electricity, your air conditioner will not

work. Please call your utility company.

2.If you have a digital thermostat and it is not displaying

a temperature, replace your batteries in the thermostat.

Back

To Top

Furnace

troubleshooting

Q.

What

to do if the furnace won't come on:

A.

1.If

you smell gas, please contact the gas supplier from

your neighbor's phone. Do not light any appliance, touch

any electrical switch or use a phone inside your home.

If you cannot reach the gas supplier, please call 911.

2.If you have no electricity, your furnace will not

work. Please call your utility company.

3.If you have a digital thermostat and it is not displaying

a temperature, replace your batteries in the thermostat.

4.If the furnace is on, but no air is coming through

the vents, call a technician for repair work.

Back

To Top

Q.

What

is SEER?

A.

Buying

a new central air conditioning system is a major investment

- both financially and in your home's comfort. The average

split-system air conditioner will last around 16 years,

so you want to make sure you choose a system that you

will be happy with for a long time. Here are some tips

for choosing a central air conditioning system:

Buy

the highest SEER you can afford. SEER stands for Seasonal

Energy Efficiency Ratio and is a measurement of the

efficiency of your cooling system over the course of

a season. The higher the SEER rating, the higher the

efficiency. Systems purchased to prior to 2006 were

mostly in the 8 to 10 SEER range. In 2006, the minimum

efficiency was raised to 13 SEER. Today, air conditioners

such as the Frigidaire iQ Drive® system can be as

high as 24.5 SEER. A 13-SEER system is 30% more efficient

than a 10-SEER system, and a 24.5 SEER system is 145%

more efficient than a 10-SEER system.

Choose

R-410A refrigerant. Most older systems used a refrigerant

called R-22. In 2010, the new refrigerant standard became

R-410A. R-410A is more environmentally friendly than

past refrigerants because it does not deplete the ozone.

Choosing an R-410A system means you may also have to

replace your line set and your indoor coil, but you

will be getting the maximum efficiency out of your new

system.

Identify

the type of system you currently have. If you have an

outdoor section and an indoor section, you have a "split

system." The split system is the most common type

of system. In the central United States and Canada,

the indoor section is the coil box that sits on top

of your gas or oil furnace. (Many homeowners think this

is part of the furnace when it is actually the indoor

section to the air conditioner.) The furnace blower

is used to distribute cool air throughout the home.

In very hot southern regions, the indoor section is

typically an electric furnace or air handler. This product

has the blower and coil inside a single cabinet. If

you do not have an indoor section, you may have a "packaged"

air conditioner. Packaged units are found in select

regions. The packaged air conditioner contains the blower

and coil components all within the outdoor section and

may even provide gas heat or electric strip heat.

Replace

the entire system, not just the air conditioner. An

air conditioner typically has two components -- the

outdoor section and the indoor section as described

above. It may be tempting to replace only the outdoor

section. But in order for your system to achieve the

efficiency you're paying for, you need to have a matched

system that includes a new indoor coil. Additionally,

old indoor components can adversely impact the performance

of your air conditioner, and your new system warranty

could be canceled if it was not installed with the proper

indoor coil or air handler.

Consider

a heat pump. A heat pump works just like an air conditioner,

cooling you all summer long. But in the fall and early

spring, it can also provide cost-effective electric

heat. Many homeowners are choosing a split-system heat

pump over a split-system air conditioner and then pairing

it with a gas furnace. This dual-fuel system can save

you a lot of money because you heat with electricity

when the weather is mild and with gas when the temperatures

dip below freezing, so you are always using the most

cost-effective fuel source to heat your home. If you

have a packaged system, there are also dual-fuel packaged

systems that combine heat pump and gas heat technology.

Don't

skimp on the install. With a heating and cooling system,

the installation is absolutely critical to performance.

Make sure you hire a certified contractor who is going

to address your ductwork and other home needs in addition

to replacing equipment. A quality installation will

cost more upfront, but it will save you in service and

headaches down the road.

Think

about comfort. Many of the higher-end air conditioners

include extra features that will dramatically improve

your home's comfort. Two-stage systems can run at a

high and low stage, so they are quieter and provide

a better mix of air throughout the home (no hot and

cold spots). Also look for noise reduction features

such as compressor sound blankets and swept-wing fan

blades. Imagine not having to turn up the television

when the air conditioner kicks on.

Back

To Top

Q.

What

is difference between 410A & R-22 refrigerant

?

A. Buying a new central air conditioning

system is a major investment - both financially and

in your home's comfort. The average split-system air

conditioner will last around 16 years, so you want to

make sure you choose a system that you will be happy

with for a long time. Here are some tips for choosing

a central air conditioning system:

Buy

the highest SEER you can afford. SEER stands for Seasonal

Energy Efficiency Ratio and is a measurement of the

efficiency of your cooling system over the course of

a season. The higher the SEER rating, the higher the

efficiency. Systems purchased to prior to 2006 were

mostly in the 8 to 10 SEER range. In 2006, the minimum

efficiency was raised to 13 SEER. Today, air conditioners

such as the Frigidaire iQ Drive® system can be as

high as 24.5 SEER. A 13-SEER system is 30% more efficient

than a 10-SEER system, and a 24.5 SEER system is 145%

more efficient than a 10-SEER system.

Choose

R-410A refrigerant. Most older systems used a refrigerant

called R-22. In 2010, the new refrigerant standard became

R-410A. R-410A is more environmentally friendly than

past refrigerants because it does not deplete the ozone.

Choosing an R-410A system means you may also have to

replace your line set and your indoor coil, but you

will be getting the maximum efficiency out of your new

system.

Identify

the type of system you currently have. If you have an

outdoor section and an indoor section, you have a "split

system." The split system is the most common type

of system. In the central United States and Canada,

the indoor section is the coil box that sits on top

of your gas or oil furnace. (Many homeowners think this

is part of the furnace when it is actually the indoor

section to the air conditioner.) The furnace blower

is used to distribute cool air throughout the home.

In very hot southern regions, the indoor section is

typically an electric furnace or air handler. This product

has the blower and coil inside a single cabinet. If

you do not have an indoor section, you may have a "packaged"

air conditioner. Packaged units are found in select

regions. The packaged air conditioner contains the blower

and coil components all within the outdoor section and

may even provide gas heat or electric strip heat.

Replace

the entire system, not just the air conditioner. An

air conditioner typically has two components -- the

outdoor section and the indoor section as described

above. It may be tempting to replace only the outdoor

section. But in order for your system to achieve the

efficiency you're paying for, you need to have a matched

system that includes a new indoor coil. Additionally,

old indoor components can adversely impact the performance

of your air conditioner, and your new system warranty

could be canceled if it was not installed with the proper

indoor coil or air handler.

Consider

a heat pump. A heat pump works just like an air conditioner,

cooling you all summer long. But in the fall and early

spring, it can also provide cost-effective electric

heat. Many homeowners are choosing a split-system heat

pump over a split-system air conditioner and then pairing

it with a gas furnace. This dual-fuel system can save

you a lot of money because you heat with electricity

when the weather is mild and with gas when the temperatures

dip below freezing, so you are always using the most

cost-effective fuel source to heat your home. If you

have a packaged system, there are also dual-fuel packaged

systems that combine heat pump and gas heat technology.

Don't

skimp on the install. With a heating and cooling system,

the installation is absolutely critical to performance.

Make sure you hire a certified contractor who is going

to address your ductwork and other home needs in addition

to replacing equipment. A quality installation will

cost more upfront, but it will save you in service and

headaches down the road.

Think

about comfort. Many of the higher-end air conditioners

include extra features that will dramatically improve

your home's comfort. Two-stage systems can run at a

high and low stage, so they are quieter and provide

a better mix of air throughout the home (no hot and

cold spots). Also look for noise reduction features

such as compressor sound blankets and swept-wing fan

blades. Imagine not having to turn up the television

when the air conditioner kicks on.

Back

To Top

Q.

What type of air conditioner do

I have?

A.

Identify the type of system you currently have.

If you have an outdoor section and an indoor section,

you have a "split system." The split system

is the most common type of system. In the central United

States and Canada, the indoor section is the coil box

that sits on top of your gas or oil furnace. (Many homeowners

think this is part of the furnace when it is actually

the indoor section to the air conditioner.) The furnace

blower is used to distribute cool air throughout the

home. In very hot southern regions, the indoor section

is typically an electric furnace or air handler. This

product has the blower and coil inside a single cabinet.

If you do not have an indoor section, you may have a

"packaged" air conditioner. Packaged units

are found in select regions. The packaged air conditioner

contains the blower and coil components all within the

outdoor section and may even provide gas heat or electric

strip heat.

Back

To Top

Q.

How

to select the right contractor ?

A.

There are two major influences on getting the best heating

and cooling system to fit your needs:

Know

what to ask the contractor. Because heating or cooling

purchases are infrequent, you may not be aware of the

various product solutions that are available to correct

common indoor comfort problems. If you do not speak

up, the contractor may assume you are not interested

in saving energy, lowering utility costs, or correcting

hot and cold spots in your home. Check out our tips

on what questions to ask.

Select

a skilled contractor. When it comes to central heating

and cooling, product performance and reliability greatly

depend on the contractor's ability to design and install

a system compatible for your home.

Here's

how to make sure you are selecting the right dealer

for your new heating and cooling system. An appropriately

sized system that is also installed correctly is critical

to performance and your happiness.

•Check

to see if the dealer possesses all of the appropriate

licensing for installing HVAC equipment in your state

and local area.

•Review the dealer's listing on the Better Business

Bureau.

•Ask how long they have been in business and if

they offer 24/7 service, financing or accept credit

cards.

•A dealer coming into your home should do more

than just inspect your existing system. Follow the dealer

around to see if he or she is checking air flow, inspecting

the duct system, making note of the windows and the

direction your home faces, etc.

•Be wary of anyone who quotes you a price on the

back of a business card after being in your home for

a few minutes, or even over the phone.

•A knowledgeable dealer that has your best interest

in mind will ask about your experiences in the home

-- how long you have lived there, how long you plan

to stay, if you have pets, allergies, smokers, hot and

cold spots and noise.

•A dealer with the tools to address these problems

will offer viable solutions such as air cleaners, zoning

equipment, programmable thermostats, humidifiers, variable

speed and two-stage technology. If they do not offer

these solutions, they may not be the right dealer for

you.

•It takes more time to complete an installation

when done correctly. Expect to pay more for comprehensive

service, but much less in the long run for your system's

performance and maintenance.

•Typically, manufacturer warranties cover the

replacement of faulty components for a limited time.

Failure due to poor installation is typically not warranted

by manufacturers. Select a dealer who will do a good

job the first time and be around to assist you as needed.

The Air Conditioning Contractors of America (ACCA) suggests

this worksheet to evaluate a potential contractor.

Back

To Top

Q.

What you can expect from your

contractor ?

A.

Here are the things you can expect a qualified heating

and cooling dealer to address when you are purchasing

a new system:

•Selecting

the type of system and equipment (plus operating and

safety controls) that are compatible with the architecture

of your home, fuel availability, fuel costs, the space

available for equipment and duct runs, appearance issues

and project cost.

•Calculating energy savings with a new system.

You may find that investing in a new energy-efficient

system with yield monthly savings greater than money

earned on a CD investment or savings account.

•Performing load or sizing calculations for each

room and the load on the central unit(s). New homes

are better insulated and do not have the same capacity

requirements as older homes. Over-sizing a unit can

contribute to uncomfortable temperatures and inefficient

performance.

•Using the proper industry manual procedures and

manufacturer's data to select, size and place equipment,

supply outlets, ducts and returns.

•Disposing of old equipment.

•Installing to local, state and federal codes

and utility regulations.

•Installing the indoor and outdoor equipment.

A split system is the most common installation.

•Installing the refrigerant lines.

•Installing supply air outlets and returns if

they do not exist or are inadequate.

•Installing duct runs (must be sealed and insulated

to R-6 or R-8 if in unconditioned space) if they do

not exist or are inadequate.

•Installing control system(s), such as thermostats

and/or zoning controls.

•Installing furnace gas piping and vent (if applicable).

•Charging the refrigerant system.

•Checking all control cycles.

•Checking refrigerant charge.

•Checking all power supplies, connections, fuel

trains and vents.

•Measuring and adjusting air flow at the unit

and at the rooms (balancing work).

•Educating the homeowner about the system and

equipment (provide all instructions and manufacturer's

documents, including warranties).

Back

To Top

Here

are some common heating and cooling terms and their

definitions. Getting up to speed on industry terms will

help you better understand your dealer’s proposal.

AFUE:

Annual Fuel Utilization Efficiency. The AFUE percentage

tells you how much energy is being converted to heat.

The higher the number, the greater the efficiency.

Air

Handler: The portion of your heating

and cooling system that forces air through your home's

ductwork.

BTU:

British Thermal Units. The amount of heat it takes to

raise one pound of water one degree Fahrenheit. The

higher the BTU rating, the larger the heating capacity

of the furnace or air conditioner.

Capacity:

The ability of a heating or cooling system to heat or

cool a given amount of space. Heating is usually expressed

in BTUs; cooling is expressed in tons.

Certified

matched system: The Air Conditioning,

Heating and Refrigeration Institute (AHRI) puts heating

and cooling equipment through rigorous certification

processes to ensure systems deliver the promised performance

at certain test conditions.

Compressor:

The motor/pump that drives the air conditioning unit.

It is responsible for pumping refrigerant throughout

the system.

Condenser

Coil: Part of the outdoor portion of

a heating or cooling system, which releases or collects

heat from the outside air.

Damper:

A valve or moveable plate used in ductwork that opens

and closes to control airflow. They are used to direct

air to specific areas of the home.

Downflow:

A type of furnace that takes cool air from the top and

blows warm air to the bottom.

Ductwork:

Hollow metal pipes used to transfer air throughout your

house.

ecoLogic:

Frigidaire’s designation of green heating and

cooling equipment. Learn More About ecoLogic.

Electronic

Air Cleaner: An electronic device that

filters out particles and contaminants in indoor air.

Evaporator

Coil: Part of the heating or cooling

system located indoors that cools and dehumidifies the

air by converting liquid refrigerant into gas.

Heat

Exchanger: The major part of the furnace

that transfers heat into your home.

Heat

Pump: A unit that handles both heating

and cooling. In some climates, a heat pump may handle

your heating and cooling needs more efficiently than

a furnace and air conditioner.

Horizontal

Flow: A type of furnace, installed on

its side, which draws air from one side, heats the air

and then sends it out the other side.

HSPF:

Heating Seasonal Performance Factor. Measures the heating

efficiency of a heat pump. The higher the number, the

more efficient the heat pump heats your home.

Humidifier:

A piece of equipment that adds moisture to the air as

it comes out of the furnace.

HVAC:

Heating, Ventilation, and Air Conditioning.

Refrigerant:

A chemical that cools air as it evaporates.

SEER:

Seasonal Energy Efficiency Ratio. SEER measures a unit's

cooling efficiency. The higher the number, the greater

the efficiency.

Single

Package: An outdoor unit that contains

both a heating and a cooling system.

Split

System: Refers to an air conditioner

or heat pump that is combined with indoor components,

such as an evaporator coil inside and a condenser coil

outside your home.

Thermostat:

A device that monitors and controls your temperature

inside your home.

Ton

(of air conditioning): A ton of air conditioning refers

to capacity in relation to melting one ton of ice in

24 hours. The capacity is measured in British Thermal

Units (Btu); 288,000 Btu are required to melt one ton

of ice in 24 hours (or 12,000 Btu/hr). A 2-ton air conditioner

has a nominal capacity of about 24,000 Btu/h.

Upflow:

A type of furnace that draws cool air from the bottom

and blows the warmed air out the top.

Ventilator:

A ventilator captures heating or cooling energy from

stale indoor air and transfers it to fresh incoming

air.

Zone:

Zoning allows you to control the heating and cooling

delivered to specific areas of your house for a custom

solution. Zoning can increase efficiency and comfort

in the area of the house you use most often.

Back

To Top

Q.

How to choose the right HVAC system

A.

There are two major influences on getting the best

system to fit your needs:

Select

a skilled contractor. When it comes to central heating

and cooling, product performance and reliability greatly

depend on the contractor's ability to design and install

a system compatible for your home. Check out our tips

on how to select the right contractor.

Have

an idea of what you want. Because heating or cooling

purchases are infrequent, you may not be aware of the

various product solutions that are available to correct

common indoor comfort problems. If you do not speak

up, the contractor may assume you are not interested

in saving energy, lowering utility costs, correcting

hot and cold spots in your home or a host of other solutions.

The

best way to purchase a system you will be most satisfied

with is to identify all the things that you would like

to improve on from your current system. Some contractors

will ask you these questions, but some may not. Therefore,

educate yourself what you want your system to do for

you.

An

HVAC purchase is a long-term commitment, so now is the

time to get the system that will satisfy your family's

needs. You can do this by reviewing the questions below.

Do

you want to lower your energy bills?

•If

you have high gas bills in the winter, ask about 95%

furnaces or higher.

•If you have high electric bills in the summer,

ask about 15 SEER or higher.

Would you like to reduce the amount of hot and cold

spots in your home?

•If

there are hot/cold spots predominately during mild temperature

days, then ask about your multi-stage options.

•Basic two-stage systems rely on two stages of

heating or cooling to give better comfort during mild

temperature days.

•Better two-stage systems use two stages of heating

and cooling plus a variable-speed blower to provide

more even temperature and fresh air in the home.

•The best is a modulating system that offers a

multitude of stages to provide the most precise temperature

control and comfort. Not all manufacturers have indoor

and outdoor modulating systems like Frigidaire.

Do you want to control temperature by room?

•Zoning

systems are designed to allow the homeowner to control

the temperature by room. You can zone as little as two

areas or you can zone up to eight. The ability to zone

your home, and the approach to zoning, may vary depending

on both the home layout and contractor skill.

Is it too humid in your home?

Does

it get too dry in the home?

Do

you have pets and the resulting dust and dander?

Is

dust a problem in your home?

Does

anyone in your family have allergies?

Back

To Top

Q.

What is Central air conditioning

?

A.

Central air conditioning, commonly referred to as central

air (U.S.) or air-con (UK), is an air conditioning system

that uses ducts to distribute cooled and/or dehumidified

air to more than one room, or uses pipes to distribute

chilled water to heat exchangers in more than one room,

and which is not plugged into a standard electrical

outlet.

With

a typical split system, the condenser and compressor

are located in an outdoor unit; the evaporator is mounted

in the air handler unit. With a package system, all

components are located in a single outdoor unit that

may be located on the ground or roof.

Central

air conditioning performs like a regular air conditioner

but has several added benefits:

When

the air handling unit turns on, room air is drawn in

from various parts of the building through return-air

ducts. This air is pulled through a filter where airborne

particles such as dust and lint are removed. Sophisticated

filters may remove microscopic pollutants as well. The

filtered air is routed to air supply ductwork that carries

it back to rooms. Whenever the air conditioner is running,

this cycle repeats continually.

Because the condenser unit (with its fan and the compressor)

is located outside the home, it offers a lower level

of indoor noise than a free-standing air conditioning

unit.

Back

To Top

Q.

What is Air Handler ?

A.

An air handler, or air handling unit (often abbreviated

to AHU), is a device used to condition and circulate

air as part of a heating, ventilating, and air-conditioning

(HVAC) system. An air handler is usually a large metal

box containing a blower, heating or cooling elements,

filter racks or chambers, sound attenuators, and dampers.

Air handlers usually connect to ductwork that distributes

the conditioned air through the building and returns

it to the AHU. Sometimes AHUs discharge (supply) and

admit (return) air directly to and from the space served

without ductwork.

Small

air handlers, for local use, are called terminal units,

and may only include an air filter, coil, and blower;

these simple terminal units are called blower coils

or fan coil units. A larger air handler that conditions

100% outside air, and no recirculated air, is known

as a makeup air unit (MAU). An air handler designed

for outdoor use, typically on roofs, is known as a packaged

unit (PU) or rooftop unit (RTU).

Blower/fanAir

handlers typically employ a large squirrel

cage blower driven by an AC induction electric motor

to move the air. The blower may operate at a single

speed, offer a variety of set speeds, or be driven by

a Variable Frequency Drive to allow a wide range of

air flow rates. Flow rate may also be controlled by

inlet vanes or outlet dampers on the fan. Some residential

air handlers (central 'furnaces' or 'air conditioners')

use a brushless DC electric motor that has variable

speed capabilities.

Multiple

blowers may be present in large commercial air handling

units, typically placed at the end of the AHU and the

beginning of the supply ductwork (therefore also called

"supply fans"). They are often augmented by

fans in the return air duct ("return fans")

pushing the air into the AHU.

Back

To Top

Q.

What is A Heat Pump ?

A

heat pump is a machine or device that diverts heat from

one location (the 'source') at a lower temperature to

another location (the 'sink' or 'heat sink') at a higher

temperature using mechanical work or a high-temperature

heat source.A heat pump can be used to provide heating

or cooling. Even though the heat pump can heat, it still

uses the same basic refrigeration cycle to do this.

In other words a heat pump can change which coil is

the condenser and which the evaporator. This is normally

achieved by a reversing valve. In cooler climates it

is common to have heat pumps that are designed only

to provide heating.

Common

examples are food refrigerators and freezers, air conditioners,

and reversible-cycle heat pumps for providing building

space heating. In heating, ventilation, and air conditioning

(HVAC) applications, a heat pump normally refers to

a vapor-compression refrigeration device that includes

a reversing valve and optimized heat exchangers so that

the direction of heat flow may be reversed. Most commonly,

heat pumps draw heat from the air or from the ground.

Heat

pumps have the ability to move heat energy from one

environment to another, and in either direction. This

allows the heat pump to bring heat into an occupied

space, or to take it out. In the cooling mode a heat

pump works the same as an ordinary air conditioner (A/C).

A heat pump uses an intermediate fluid called a refrigerant

which absorbs heat as it vaporizes and releases the

heat when it is condensed. It uses an evaporator to

absorb heat from inside an occupied space and rejects

this heat to the outside through the condenser. The

refrigerant flows outside of the space to be conditioned,

where the condenser and compressor are located, while

the evaporator is inside. The key component that makes

a heat pump different from an air conditioner is the

reversing valve. The reversing valve allows for the

flow direction of the refrigerant to be changed. This

allows the heat to be pumped in either direction.[citation

needed]

In

heating mode the outdoor coil becomes the evaporator,

while the indoor becomes the condenser which absorbs

the heat from the refrigerant and dissipates to the

air flowing through it. The air outside even at 0 °C

(or at any temperature above absolute zero) has heat

energy in it. With the refrigerant flowing in the opposite

direction the evaporator (outdoor coil) is absorbing

the heat from the air and moving it inside. Once it

picks up heat it is compressed and then sent to the

condenser (indoor coil). The indoor coil then injects

the heat into the air handler, which moves the heated

air throughout the house.

In cooling mode the outdoor coil is now the condenser.

This makes the indoor coil now the evaporator. The indoor

coil is now the evaporator in the sense that it is going

to be used to absorb the heat from inside the enclosed

space. The evaporator absorbs the heat from the inside,

and takes it to the condenser where it is rejected into

the outside air.

Back

To Top

Q.

What Is A Condenser?

What

is a condenser? Many people have air conditioners but

are not aware of how or what makes them work. A condenser

is simply one component of an air conditioner. Whether

you have an outdoor air conditioner or a window unit

air conditioner your air conditioner contains a condenser.

Condensers

are used in outdoor air conditioning systems as well

as heat pump systems. Condensers in an air conditioning

unit have very few controls. They will have an on and

off switch. Occasionally these air conditioners will

also have a brown out option. This option shuts down

the compressor when the electrical current is low.

A

condenser is simply a heat exchanger. It compresses

refrigerants into a hot gas to then condense them into

a liquid. A condenser is a major component in a air

conditioning or heat pump unit. It moves air across

the coils to facilitate the transfer of heat.

In

a heat pump unit the condenser has a few more features.

It will have a reverse valve that allows the unit to

switch back and forth between air conditioning and heating.

Even when the unit is heating, it uses the condenser

for defrosting the coils. If the coils become layered

with frost it will effect the units effectiveness this

is defrosted when the reverse valve switches to air

conditioning mode to move the hot gases through the

coils melting the built up ice. It will automatically

switch back to heating mode once the ice is cleared

to once again heat the home.

It

is very important no matter what type of unit you have

to prevent the blockage of the condenser. If the condenser

becomes block it can effect the units efficiency or

even cause the until to completely fail. For this reason

it is one of the most important components of a cooling

or heating system. A condenser allows the maximum airflow

to the unit.

To

keep your unit in good operating condition it is vital

to keep the area around the condenser clear of all debris

as well as keeping the filter clear of dust and dirt.

A clean machine makes a happy machine. A happy machine

will keep you cool during the summer months and warm

during the cold months. It is suggested to change the

units filters when they become dirty, depending on your

area and conditions near your home this may be as often

as once a month or as seldom as every 3 to 6 months.

You will have to pay close attention to your units needs

to decide the right time to change or clean your units

filters.

Keeping

you condenser in good running condition will not only

prolong the life of your heat or cooling system but

also provide you with the most efficient heat and cooling

system saving you money on heat and cooling.

Back

To Top

What

Is an Air Compressor ?

An

air compressor increases the amount of air in a particular

space. By packing in the air, the air pressure is increased

which creates a force that is useful for a variety of

purposes, from industrial and manufacturing to commercial

and personal purposes.

The

original air compressor is the lung. When you take a

deep breath to blow out your birthday candles, for example,

you're increasing the pressure of the air in your lungs,

which effectively is an air compressor containing pressurized

air. You then use the force of the air in your lungs

to blow out the flames of your birthday candles.

Eventually,

man-made air compressors were created. These fall generally

fall into one of two types, positive displacement or

dynamic, defined by its mode of operation. A positive

displacement air compressor works by filling and then

emptying an air chamber. Three common types of positive

displacement air compressors are: reciprocating, rotary

screw and rotary sliding vane. A dynamic air compressor,

on the other hand, uses a a rotating device to accelerate

and then decelerate air. This process uses the speed

or velocity of the air to increase the air's pressure.

Centrifugal air compressors are dynamic air compressors.

Compressed

air can be used in a variety of ways. It can be used

to alter the chemical composition as in the case of

making fertilizer or it can be used for industrial purposes

like production line manufacturing processes or it can

be used to maintain industrial plants. Perhaps the most

well known use of the air compressor is in the case

of pneumatic tools like air powered nail guns, staplers,

sanders, spray guns, or ratchet wrenches. Air compressors

can also be used to move debris. These tools are commonly

available at hardware stores for purchase or rental.

Another

way to group air compressor types is by the number of

stages it has. A two-stage air compressor is usually

used for heavy duty use. This type of unit offers a

higher level of compression than smaller, single stage

air compressors. A two-stage air compressor can store

air for future use, and is more energy efficient since

it produces more air per unit of horsepower than a single

stage compressor. Also, less heat is generated in a

two-stage compressor, which means that wear on the unit

is reduced. Portable electric air compressors are also

available for light-duty applications.

Depending

on the type of air compressor, operation costs can be

high, as in the case of plant maintenance. While air

compressors can run on manual labor, like a hand powered

air compressors, most run on either electricity or natural

gas. It's the natural gas air compressor that is usually

more cost-effective. If the air compressor is used in

a small, enclosed area, an electric model may be more

desirable in order to avoid gas fumes.

The

American Society of Mechanical Engineers (ASME) attests

to the quality and protective features of air compressors.

Their rating can be considered in evaluating air compressors

for purchase or rental. In some states, only ASME-certified

air compressors may be sold. Some safety features include

a safety relief valve, which lets air escape if the

tank's pressure exceeds the maximum. The air compressor

should also have a belt guard for protection, and an

enclosed air intake filtration system.

As

with all tools, proper safety should exercised when

using an air compressor. When not being used, air compressors

should be properly powered off and unplugged.

Back

To Top

How

does the heat work In central Air conditioners as Heat

Pumps?

Heat

pumps and most central air conditioners are called "split

systems" because there is an outdoor unit (called

a condenser) and an indoor unit (an evaporator coil).

The job of the heat pump or air conditioner is to transport

heat from one of these units to the other. In the summer,

for example, the system extracts heat from indoor air

and transfers it outside, leaving cooled indoor air

to be recirculated through your ducts by a fan.

A

substance called a refrigerant carries the heat from

one area to another. Basically, here's how it works:

The

compressor in your outdoor unit will change the gaseous

refrigerant into a high temperature, high-pressure gas.

As that gas flows through the outdoor coil, it loses

heat. That makes the refrigerant condense into a high

temperature, high pressure liquid that flows through

copper tubing into the evaporator coil located in your

fan coil unit or attached to your furnace.

At

that point, the liquid refrigerant is allowed to expand,

turning the liquid refrigerant into a low temperature,

low pressure gas. The gas then absorbs heat from the

air circulating in your home's ductwork, leaving it

full of cooler air to be distributed throughout the

house. Meanwhile, the low temperature, low pressure

refrigerant gas returns to the compressor to begin the

cycle all over again.

While

your air conditioner or heat pump cools the air, it

also dehumidifies it. That's because warm air passing

over the indoor evaporator coil cannot hold as much

moisture as it carried at a higher temperature, before

it was cooled. The extra moisture condenses on the outside

of the coils and is carried away through a drain. The

process is similar to what happens on a hot, humid day,

when condensed moisture beads up on the outside of a

glass of cold lemonade.

The

same process works in reverse in a heat pump during

the winter. The heat pump takes heat out of the outside

air - or out of the ground, if you have a geothermal

heat pump - and it moves that heat inside, where it

is transferred from the evaporator coil to the air circulating

through your home.

That's

not a typographical error, by the way- the heat pump

moves heat from outside to warm your home, even on a

cold day. That's because "cold" is a relative

term. Air as cold as 30 degrees still contains a great

deal of heat - the temperature at which air no longer

carries any heat is well below -200 degrees Fahrenheit.

A heat pump's heat exchanger can squeeze heat out of

cold air, then transfer that heat into your home with

the help of a fan which circulates the warm air through

your ducts.

Heat

pumps are often installed with back-up electric resistance

heat or a furnace to handle heating requirements when

more heat is needed than the heat pump can efficiently

extract from the air.

Back

To Top

What's the best way to

ensure that the central air-conditioning system you

choose is installed properly, and will provide the most

efficient and reliable cooling for your home?

The

pointers below can help you to find the right hardware

and the right technician to install your system, whether

you're replacing an older air conditioner or installing

one for the first time. The information comes from our

experts.

And

while there's no one money-saving strategy that will

work for everyone all the time, there are simple steps

that you can take, as we show in Keeping costs down.

In some cases, you may be able to cut back on air-conditioner

use considerably without seriously inconveniencing your

family.

Design

In a "split system," the typical design, refrigerant

circulates between an indoor coil and a matching outdoor

condenser with compressor. The refrigerant cools the

air, dehumidifying it in the process; a blower circulates

air through ducts throughout the house. A variation

is the "heat pump," a type of system that

functions as heater and cooler. When used as an air

conditioner, a heat pump discharges heat from the house

either into the air or deep into the ground. In the

winter, a heat pump extracts heat from the ground or

the air to warm the house.

Efficiency

This describes how much cooling the unit delivers for

each watt of electricity. Efficiency is expressed as

the Seasonal Energy Efficiency Rating, or SEER. At present,

a SEER of 10 denotes a low-efficiency unit; medium efficiency

is 11 to 14; high efficiency is above 14. New federal

regulations that took effect in 2006 set the minimum

SEER for a central air conditioner at 13.

Size

A synonym for the air conditioner's cooling capacity,

size is measured in British thermal units per hour (Btu/hr.)

or in "tons." One ton of cooling equals 12,000

Btu/hr.

Get

the right contractor

Finding a trustworthy contractor to install and service

an air-conditioning system matters the most. Here's

how to choose:

Ask

around

Seek referrals from neighbors, family, or business associates.

It's wise to get price quotes from at least three contractors.

Check

the background

Contractors who bid on your installation should show

you proof of bonding and insurance, plus any required

contractor's licenses. Check with your local Better

Business Bureau and consumer affairs office for complaint

records. It's a plus if technicians are certified by

a trade organization, such as North American Technician

Excellence or HVAC Excellence, to service residential

heating and cooling equipment. These and other similar

programs assess the technician's knowledge of specific

types of equipment and its proper service methods. We

believe that a contractor who has made the effort to

get certified and has practiced this trade and learned

from several years of service and installation experience,

will be a better service provider.

Get

specifics

Contractors who bid on your job should calculate required

cooling capacity by using a recognized method like the

Air Conditioning Contractors of America's Residential

Load Calculation Manual, also called Manual J. An additional

reference for assessing ductwork needs is Manual D.

The calculations produce a detailed room-by-room analysis

of cooling needs. Ask for a printout of all calculations

and assumptions, including ductwork design. Be leery

of a contractor who bases estimates merely on house

size or vague rules of thumb.

Expect

maintenance

A service plan that combines regular inspections with

discounts on repairs and a labor warranty is worth negotiating

into the overall price. Prices for such service vary

widely.

At

a minimum, regular inspections should include these

steps:

Check

for and repair refrigerant leaks.

Detect and correct duct leaks.

Inspect and tighten the electrical connections, checking

for damage.

Clean the coils, drain pan, and drainage system.

Vacuum the blower compartment.

Replace filter monthly or as recommended by the manufacturer.

Choose the right unit

If you're replacing an old central-air system, you can

expect to pay around $3,000 for the equipment. If you

need ductwork installed because you're starting completely

from scratch or are upgrading a forced-air heating system,

expect to pay $6,000 or more. Improving the system's

air-filtration capabilities is also easiest to do as

part of a general upgrade.

Brand

plays some role in the selection.

Here

are other factors that may affect reliability:

Matching

new equipment with old. If you replace only the condenser,

you have a "field-matched" system that can

be less efficient than advertised and that may require

more repairs because of undetected incompatibilities

between the two.

Damper-zoned cooling. A large or multistory house is

often divided into several heating and cooling zones

to improve temperature control. However, this type of

system is complex and has many more moving parts and

controls and so may require more repairs.

Back

To Top

HOW

TO MAINTAIN CENTRAL DUCT AIR CONDITIONING SYSTEM?

1.Troubleshoot

a Central Air Conditioning System

.........

.........

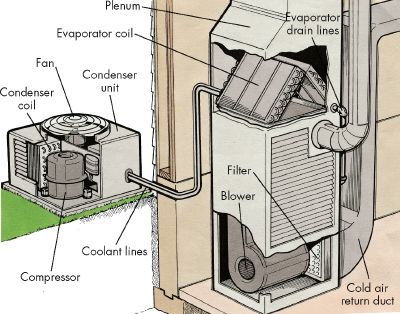

Central

air conditioners have two separate components: the condenser

and the evaporator. The condenser unit is usually

located outside the house on a concrete slab. The evaporator

coil is mounted in the plenum or main duct junction

above the furnace.

Most

central air conditioners are connected to a home's forced-air

distribution system. Thus, the same motor, blower, and

ductwork used for heating are used to distribute cool

air from the air conditioning system. When a central

air conditioner is operating, hot air inside the house

flows to the furnace through the return-air duct. The

hot air is moved by the blower across the cooled evaporator

coil in the plenum and is then delivered through ducts

to cool the house. When the air conditioner works but

the house doesn't cool, the problem is probably in the

distribution system.

Both

the evaporator and the condenser are sealed. Therefore,

a professional service person should be called for almost

any maintenance other than routine cleaning. Central

air conditioners should be professionally inspected

and adjusted before the beginning of every cooling season.

However, don't let your maintenance end with this annual

checkup. While there aren't many repairs you can make

yourself, there are specific maintenance procedures

you can follow to keep your system operating at peak

efficiency.

Caution:

Before doing any work on an air conditioning system,

make sure the power to the system, both to the condenser

and to the evaporator assembly, is turned off.

2.Cleaning

the Evaporator

Cleaning

the Evaporator

The evaporator for the central air system is located

directly above the furnace in the plenum. The evaporator

may not be accessible, but if it is, you should clean

it once a year. If the plenum has foil-wrapped

insulation at its front, you can clean the evaporator;

if the plenum is a sealed sheet metal box, do not attempt

to open it. Here's how to clean an accessible evaporator:

Step

1: Remove foil-wrapped insulation at front of plenum;

it's probably taped in place. Remove tape carefully,

because you'll have to replace it later. Behind insulation

is access plate, which is held in place by several screws.

Remove screws and lift off plate.

Step

2: Clean entire underside of evaporator unit with stiff

brush. A large hand mirror can help you see what you're

doing. If you can't reach all the way back to clean

entire area, slide evaporator out a little. Evaporator

can be slid out even if it has rigid pipes connected

to it, but be careful not to bend pipes.

Step

3: Clean tray below evaporator unit. This tray carries

condensation away from evaporator. Pour 1 tablespoon

of household bleach into weep hole in tray to prevent

fungus growth. In extremely humid weather, check condensate

drain and pan every other day. If there's much moisture

in pan, weep hole from pan to drain line may be clogged.

Open weep hole with piece of wire.

Step

4: Put unit back into place, reinstall plate, and tape

insulation back over it.

Step

5: Turn back on air conditioner, and check for air leaks.

Seal any leaks with duct tape

3.Maintaining

the Condenser

Maintaining

the Condenser

In most air-conditioning systems, the condenser unit

is located outside the house and is prone to accumulate

dirt and debris from trees, lawn mowing, and airborne

dust. The condenser has a fan that moves air across

the condenser coil. You must clean the coil on the intake

side, so, before you turn off the power to the air conditioner,

check to see which direction the air moves across the

coils. Here's how to clean the condenser:

Step

1: Cut down any grass, weeds, or vines that have grown

around condenser unit; they could be obstructing airflow.

Step

2: Clean condenser with commercial coil cleaner, available

at refrigerator supply stores. Instructions for use

are included. Flush coil clean (do not use hose); let

dry.

Step

3: Clean fins with soft brush to remove accumulated

dirt. You may have to remove protective grille to reach

them. Do not clean fins with garden hose, as water could

turn dirt into mud and compact it between fins. Clean

fins very carefully: They're made of light-gauge aluminum

and are easily damaged. If fins are bent, straighten

them with fin comb, sold at most appliance parts stores.

A fin comb is designed to slide into spaces between

fins. Use it carefully to avoid damaging fins.

Step

4: Check concrete pad on which condenser rests to make

sure it's level. Set carpenters' level front to back

and side to side on top of unit. If pad has settled,

lift pad with pry bar or piece of 2-by-4, then force

gravel or rocks under concrete to level it.

During

the fall and winter, outside condenser units should

be protected from the elements to prevent leaf blockage

and ice damage. Cover the condenser unit with a commercial

condenser cover made to fit the shape of the unit or

use heavy plastic sheeting secured with sturdy cord

4.Handling

the Refrigerant (Only with help of licensed HVAC Contractor)

The

coolant used in most air conditioning systems is a refrigerant

called Freon. If the system does not contain the proper

amount of Freon, little or no cooling will take place.

If you suspect a Freon problem, call a professional

service person to recharge the system. Caution: Do not

try to charge your system's refrigerant lines.

Here's

how you can repair the system's coolant lines. Examine

the lines running from the condenser outside the evaporator

inside the house. If the insulation is damaged or worn,

it will cut down on the cooling efficiency of the unit

and, therefore, should be replaced.

Replace

damaged or worn coolant line insulation with new insulation

of the same type as soon as possible. Follow manufacturer's

instructions for installation.

Many

homes or apartments use window-unit air conditioners,

so it's also important to know how to maintain or service

these smaller units. Learn how to head off problems

and keep these units running smoothly in the next section.

5.Thermostat

The thermostat is located behind the control panel.

Here's how to test and/or replace the thermostat:

Step

1: Remove grille and control panel from unit. Thermostat

has special sensing bulb attached to it; this part extends

from thermostat into evaporator coil area. Its role

is to sense temperature, which is controlled by thermostat.

Step

2: Remove thermostat carefully because you must return

sensing bulb to identical spot later. To make replacement

easier, tag location of bulb before you remove thermostat.

Step

3: Check thermostat with VOM set to RX1 scale. Clip

probes of tester to thermostat terminals, and turn temperature

control dial to coldest setting. If meter reads zero,

thermostat is functioning properly. If reading is higher

than zero, replace thermostat with new one of same type.

If thermostat is held to control panel or frame with

screws, clips, or metal tabs, connect new thermostat

the same way the old one was connected.

Note:

If the thermostat has more than two lead wires connected

to it (not counting the sensing bulb wire) do not try

to test or replace it. Instead, call a professional

service person.

Drain

Ports

As the air conditioner operates, condensed moisture

and water vapor from the evaporator coil are funneled

through drain ports or an opening between the partition

in the middle of the evaporator coil and the condenser

coil. At this point, the fan blows the moisture against

the condenser coil, where the water is dissipated.

Drain

ports can become clogged with dirt. The result is water

leaking from the appliance, usually through the bottom

of the grille. To prevent clogging, clean the ports

with a short piece of wire hanger or the blade of a

pocketknife. Do this at the beginning of every cooling

season and every month during the season. Also check

the condenser side of the air conditioner. Some models

have a drain port along the bottom edge of the cabinet

frame. If your air conditioner has this drain port,

clean it out when you clean the other ports.

The

fan, motor, and compressor require routine maintenance

to keep your air-conditioning unit running at its most

efficient. The following are some simple guidelines.

6.Fan

When a fan malfunctions, the problem is usually loose

or dirty blades. If the fan won't operate or if it's

noisy, cleaning and tightening will usually fix it.

Here's how to repair a room air conditioner's fan:

Step

1: Open cabinet and locate fan.

Step

2: Clean away any debris with vacuum and soft cloth.

Step

3: Check fan blade on motor shaft for looseness. Blade

is fastened to shaft with setscrew at hub of blade.

Tighten

setscrew with screwdriver or Allen wrench. If air conditioner

has round vent fan, tighten fan on motor shaft by inserting

long-blade screwdriver through port in fan.

Fan

is installed in its housing with bolts, and vibration

can loosen these fasteners. Then tighten them with wrench.

Step

4: If fan has oil ports, apply several drops of 20-weight

nondetergent motor oil (not all-purpose oil) to each

port at beginning of cooling season.

Step

5: If you suspect fan motor is faulty, test it with

VOM set to RX1 scale. Disconnect terminal wires from

terminals, and clip probes of VOM to wires.

If

meter reads between about 3 and 30 ohms, motor is functioning

properly. If meter reads either zero or an extremely

high number, replace motor.

To

remove the fan motor, remove the fan, the power wires,

and several mounting bolts. Install the new motor with

the reverse procedure. However, if the condenser coil

must be moved to get the fan out, do not try to remove

the motor. Call a professional service person.

Motor

and Compressor

If problems occur in the motor or compressor of the

air conditioner, call a professional service person.

By

following the routine maintenance mentioned in this

article, you will be able to handle most problems that

occur with your central air conditioning or window unit.

Tips

for Buying or Upgrading your Central Duct Air Conditioning

System.

If you've been thinking of upgrading your old central

air-conditioning system, or installing central air in

a house that has never had it, there's a lot to consider.

Every manufacturer today offers a wide range of products,

with one suited to nearly every situation. A few even

make systems for houses that won't accommodate conventional

ductwork. As you might expect, the two most important

considerations are efficiency and cooling capacity,

but there's more to it than buying the biggest, most

efficient system you can afford. In fact, there's quite

a bit more.

1.

An Equipment Overview

Central

air conditioning is, of necessity, a split system, with

some components installed outdoors and others indoors.

The heaviest, noisiest, heat-shedding components–the

compressor and condenser coil–are installed outdoors,

while the evaporator coil is installed indoors, usually

in the form of an A-frame in the plenum of a forced-air

furnace. In this case, the furnace's blower moves warm

air over the coils and distributes the chilled air.

The indoor and outdoor segments of the system are typically

joined by two refrigeration lines and a low-voltage

relay cable.

If

a home is heated by some means other than forced air–baseboard

or radiant floor heat, for example–the evaporator

coil is typically mounted in a dedicated blower unit,

which pushes the cooled air through conventional ductwork.

Most blower units are installed in attics and crawlspaces

and are connected to flexible, insulated ductwork, which

is the easiest and least costly to install, especially

in retrofit situations.

In

houses built without ductwork, and where conventional

ductwork would be too costly or too inefficient to install,

a ductless central-air system is now possible. Ductless

systems have long been popular in Europe and Asia, where

building methods discourage ductwork, but are relatively

new in the United States. The Carrier Corp. is one of

several companies now making ductless systems for the

U.S. market.

In

these systems, a single outdoor compressor serves several,

smaller evaporator coils located indoors, each in its

own box and each with its own blower fan. These components

are installed on exterior walls, usually on the upper

half, where much of the heat accumulates. They're finished

unobtrusively, but they can be quite large, often measuring

6 x 18 x 24 in. Condensation lines are routed outside,

along with the refrigeration and electrical lines.

Ductless

systems can also provide heat, either through resistance

coils in the wall units or in heat-pump fashion. The

advantages of ductless air over window air are that

ductless systems move the noisiest components outdoors,

they can provide heat, they distribute the air more

evenly, and they don't block the better half of a window.

Installation costs vary widely, but ductless systems

can be more expensive than ducted systems. It's a sliding

scale, with each home's variables–primary building

material, number of rooms, house size and layout–coming

into play. They're reliable and efficient, but they're

not likely to replace ducted systems in the United States.

They're considered problem solvers, with the problem

being fairly rare.

2.

How Conventional Systems Work

All

heating and cooling technology grows from the law of

thermal dynamics that says when hot and cold spaces

are separated by a medium, the transfer through the

medium will always be from hot to cold. Heat follows

cold, whether the medium is human skin, an exterior

wall or the metal surface of an evaporator coil. When

warm, humid air is blown across the evaporator coil

in your furnace, the heat in the air is drawn to and

impinges on the cold metal surface of the coil's fin

tubes. In the process, the moisture in the air condenses

on the cold metal and drips into a pan below the coil,

where it's drained off, thus lowering the humidity in

the house.

It's

a neat trick–a double trick–but it requires

a repeatable cycle, over and over, every time the system's

thermostat demands it. The evaporator coil needs to

be constantly recooled and the heat it absorbs needs

to be carried outdoors. This is accomplished with a

liquid/gas refrigerant, which undergoes a pressure-induced

state change. An outdoor compressor pressurizes the

refrigerant, heating it to a gas state, then sends it

through an adjacent condeser coil to be cooled and returned

back to the evaporator coil. There it picks up household

heat and carries it back to the compressor. When this

cycle is repeated often enough, our homes become a lot

more comfortable.

3.

Understanding Energy Ratings

Air

conditioners have always been prodigious users of electricity,

but efficiencies have improved considerably in the past

few years. Part of this improvement was federally mandated

in 1990, through the culmination of the National Energy

Conservation Policy Act of 1971. These regulations established

minimum efficiency standards for heating and cooling

equipment. As a result, nearly all models manufactured

today are more efficient than those made just 10 or

15 years ago.

How

are systems rated? Central air conditioners–the

condenser units–are given a Seasonal Energy Efficiency

Rating, or SEER. In simple terms, SEER is calculated

by dividing the cooling capacity of a continuously operating

air conditioner by the electrical input required to

run it. The value is expressed in numbers. A SEER 10,

for example, is now the lowest number allowed, and any

number larger than that is accordingly more efficient

and will cost less to operate. Along with the yellow

Energy Guide tags attached to each appliance, these

ratings give consumers a benchmark sense of where their

choices fall on the energy-efficiency scale.

Most

manufacturers now offer SEER 10, 11, 12 and 13 models,

and some offer SEER 14. This gives you five separate

efficiency options, with model numbers usually keyed

to the SEER numbers, so they're easy to recognize. Lennox's

Value 12 system, for example, is a SEER 12.

4.How

Better Efficiencies Are Achieved

Like

the auto industry in its quest for better mileage, cooling

equipment manufacturers have combined some minor tweaking

with some major re-engineering. Because the compressor

is the biggest energy user, that's where they have focused

much of their attention. The first step was to improve

the internal components of standard, reciprocating compressors,

so that less pressure–and therefore, energy–was

lost to internal leaks. Another step was to increase

the size of the condenser coil. With more fin-tube surface

area, the returning refrigerant could be brought to

the compressor with less heat, reducing the compressor's

load.

These

two steps yielded substantial savings, bringing condensers

into federal compliance, but a complete retooling was

needed to achieve significant improvements beyond this

level. Part of the answer was a multispeed compressor.

With two or more speeds, the system doesn't have to

run full out on days when only mild cooling and dehumidification

are needed. Full-speed use is still available for those

really miserable days, but the compressor doesn't have

to run wide open all the time. At low speed, the practical

effect is that of a small compressor matched with an

oversize condenser coil. The savings can be substantial

and most manufacturers offer multispeed compressors

in their lineups.

At

the same time, engineers began testing a radically different

kind of compressor–the scroll. Scroll compressors

are so different that they practically defy description.

But their mechanical advantage is clear. Because they

generate much less friction, they experience much less

wear. The final product is a compressor that is very

efficient and lasts longer. Today, most companies offer

some multispeed and some scroll compressors, though

a few, like Ruud/Rheem, have gone to scroll compressors

exclusively, as a statement of across-the-line quality.

Any way you look at it, today's condenser units are

better than those made just a few years ago.

5.

The Freon Question

As

a result of the Montreal Protocol, a conference that

grew out of international concern over the ozone-depleting

qualities of CFC chemicals, the EPA is mandating the

gradual phaseout of Freon, or R22 refrigerant. The new,

non-ozone-depleting replacement will be R4-10A. In fact,

some manufacturers have switched to R4-10A in some models

already. While this new refrigerant works just as well,

it requires pressures up to 50% greater than Freon,

so it can't be used in existing equipment. Interestingly,

the higher operating pressure actually improves efficiency

slightly. In any case, there's no practical way to convert

existing equipment.

So

where does this leave the tens of millions of us with

Freon-based, R22 systems? The short answer is that the

Freon phaseout is stretched so far into the future that

nearly all of today's air conditioners will have been

replaced by then. The EPA will require a substantial

reduction by 2004, and all products containing R22 must

stop production by 2010. The production of R22 itself

must cease by 2020. For those few R22 units still in

service at that time, recycled R22 will be available,

though it will probably cost a small fortune.

6.

Sizing For Capacity And Efficiency

Your

heating, ventilation and air-conditioning (HVAC) contractor

will size your equipment to meet the specific needs

of your home. Factored into the equation will be the

age of your house, the number and quality of its windows,

how well it's insulated, how many stories it has, its

size, and, of course, local energy rates. Contractors

use industry sizing models, such as Model J, but most

use them as a reference, modifying the results to accommodate

their own years of experience. A 1500-sq.-ft. ranch-style

home, for example, might normally require a 2 1/2-ton

air conditioner, but if it's not well insulated, or

if a good many windows have western exposure, or if

the trees offer little direct shade, then a 3-ton unit

might be more appropriate.

In

any case, sizing is critical. If sized too small, the

system will struggle, and even freeze over, on the warmest

days. If sized too large, the system will cycle on and

off too frequently, greatly reducing its ability to

control humidity. It will also be less efficient. Keep

in mind that efficiency ratings are measured at the

factory, under conditions that may have little to do

with your house. In any case, sizing is a job best left

to seasoned professionals, and it's a good idea to seek

out more than one opinion.

7.

General Installation Costs

What

do air conditioners cost, installed? Again, local prices

will vary significantly, but in a typical Midwestern

town, a nonunion shop might charge between $1200 and

$1700 to replace an old, 3-ton air-conditioner with

a new SEER 10 system. That's assuming a 1500-sq. ft.

house, 20 years old, with ductwork in place. For a similar

home that's new, with a gas furnace and equivalent air

conditioning, the price would be $5000 to $7000, gas

and electrical connections included.

8.

The Price Vs. Efficiency Question

Of

course, you'll always pay more for high-efficiency appliances,

so the critical question is whether you'll save enough

in the long haul to come out ahead. And that, unfortunately,

requires a region-by-region, even a house-by-house,

assessment. You'll need to work closely with your contractor

to make an informed decision. Don't assume that high

efficiency always pays. It may from a good-citizenship

perspective, but real dollars should drive the rest

of the equation. And don't forget to add the cost of

interest on the money gained or lost.

All

we can do here is provide some context. If, for example,

your electricity costs you a low 6 cents per kilowatt-hour

(kwh), and you live in a reasonably well-insulated home

in the northern one-third of the nation, using your

air conditioner 200 to 400 hours per year, a basic SEER

10 system is probably your best choice. There's little

chance that you'd recover the several hundred extra

dollars a SEER 11 or SEER 12 system would cost, spread

over a 12- to 15-year projected service life. You may

hope for longer service, and you'll probably get it,

but don't count on it. A SEER 10 is also a reasonable

choice if you plan to move in the next few years.

On

the other hand, if you live in Yuma, Ariz., and run

your air conditioner 2000 hours per year, then it makes

sense to buy the most efficient model you can afford.

The same might be true if you live on the Eastern Seaboard

and pay 11 or 12 cents per kwh, or if you live in a

house with stone or brick exterior walls, where insulation

is simply not feasible. In these cases, high efficiency

really is a good investment.

Prices

vary by manufacturer and with local market pressures,

but it's probably safe to say that each step up in efficiency

will cost about $200. This may seem a paltry sum, and

it is for many people, but when you consider that the

equipment costs for an entire SEER 10 system might run

$800 to $900, an increase of $200 to $800 is significant.

9.

Quality And Warranties

Most

manufacturers offer two quality levels for each SEER

number. What you get in return is a better-made unit

that runs three to six times quieter and lasts longer.

A quieter-running unit can be a real plus if you–or

your neighbors–are particularly annoyed by a loud

air conditioner. You'll also get a better warranty:

a 10-year compressor warranty instead of five, a 5-year

warranty against leaks in the coils instead of one year.

As with all step-up warranties, you're betting against

yourself, which sometimes pays big dividends. If it

paid more than about 40% of the time, however, the manufacturer

couldn't afford to offer it.

Back

To Top

Important

information on Central ACs

Sizing

Up Your Central Air Conditioner Price Options

It takes more than a few figures and a form online to

thoroughly assess central air prices. There are several

factors that will directly affect the size of the unit

you need, what you’ll be spending up front, and

ultimately what you’ll be shelling out from month-to-month.

Central air conditioner prices go beyond the initial

cost of the unit itself, and all of these factors should

be considered when price shopping for a new air conditioning

system. The best way approximate your home cooling needs

is going to be doing a load calculation, or heat-gain

calculation. The Air Conditioning Contractors of America’s

Manual J Residential Load Calculation includes everything

from the obviously practical to the commonly overlooked

elements of home cooling, so it’s a great rubric

for determining prices of central air.

Back

To Top

Small

House, Round House, Big House: Central Air Conditioner

Prices Vary

The size of the area being cooled is an obvious factor

when it comes to sizing your potential AC unit. The

square footage of your home will directly affect your